Workmaster™ boots are manufactured at our automated state of the art footwear factory TO THE VERY HIGHEST TECHNICAL STANDARDS IN THE WORLD.

Boot Construction

How are they made?

Workmaster™ boots are manufactured at our automated state of the art footwear factory based in Crawley (in the United Kingdom). The injection moulding manufacturing process guarantees a seamless leak-free construction. This modern high-volume production facility enables the manufacture of different types and styles of boots within the same operating run, giving the flexibility to meet rapidly changing market demands.

All our boots are REACH compliant and both boots and insoles are machine washable at up to 40°C with a shelf life in excess of 10 years.

Boot Features

- Slip-resistant vulcanised rubber sole

- Steel toe cap

- Stainless steel mid-sole

- Comfort insole

- Cushioned heel

- Kick-off lug

- Adjustable height

- Single piece injection moulded construction

- Non-wicking polyester lining Not all features are present on all boots - please check the product page for the specific boot you are interested in.

Comfort Insoles

Our latest ergonomic design comfort insoles went through an extensive wearer trials program and the results demonstrated a significant improvement in cushioning and wearer comfort. Thermal insulation has also been greatly improved, with a temperature drop of only 0.5°C in the EN 20345 cold insulation test, an improvement of 90% over our previous insole.

Comfort insoles are fitted as standard to all of our boots except the Hazmax YS, Dielectric N, Solestar and Digger models, where they are available as an option. Replacement insoles are also available.

Antistatic & ESD Footwear

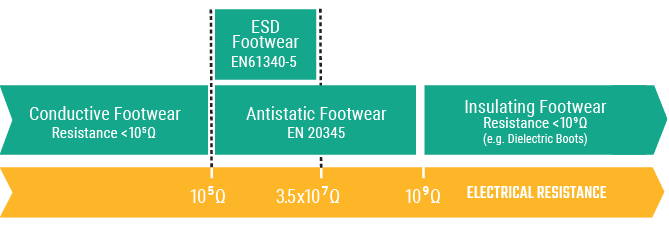

According to EN 20345: 2011, a shoe or boot is considered to be antistatic if its’ measured electrical contact resistance falls between 100 kΩ (105 ohms) and 1 GΩ (109 ohms). With a lower resistance, a shoe or boot is considered to be conductive and at higher values, to be insulating. This 100kΩ to 1GΩ range is regarded a sensible compromise, giving protection from electrostatic build up and protection from electrical shocks at lower voltages.

For some industries the risk of uncontrolled electrical discharge (sparks) in potentially explosive atmospheres or the protection of sensitive electronic components and devices are also important considerations. In these situations, another standard for Electro-Static Discharge (ESD) control applies: EN 61340-5-1 (“Electrostatics. Protection of electronic devices against electrostatic phenomena”).

For ESD footwear the lower limit of electrical resistance is 100 kΩ (the same as for antistatic footwear) and the upper limit is 35 MΩ (3.5 x 107 ohms). This means that a boot that is ESD-capable is by definition also antistatic at the same time. Conversely, not every antistatic boot is ESD-capable e.g. If an electrical resistivity of 100 MΩ is measured, the shoe is antistatic but outside the ESD limits. If the shoe has an electrical resistance of only 1 MΩ, it is both antistatic and ESD-capable.

Benefits of a Vulcanised Rubber Sole

Over 30% of industrial accidents result from slips, trips and falls - as Workmaster™ boots are frequently used in environments where there are liquids present a slip resistant sole is crucial, which is why we fit a high-performance vulcanised rubber sole to our boots.

This provides a number of important benefits:

- Slip resistance is twice that required by EN 13287 SRA and SATRA TM144 standards

- Grip is 30% better than with a conventional safety boot sole

- Wear resistance is two to three times that of conventional soles

- The sole is resistant to fuel and oil

- Greater cut resistance than conventional soles

- Resistant to hot contact for 60 seconds at 300°C

- Cold insulation

The Science of slip

As part of mandatory testing for the latest edition of the EN 20345:2022+A1:2024 standard, footwear is tested for forward heel slip resistance and backward forepart (ball of the foot) slip resistance at a 7° angle on a ceramic floor tile with a soapy water (Sodium Lauryl Suphate) solution.

An additional, more demanding test, using glycerol oil on a ceramic tile (to simulate an oily/greasy floor) can be performed; the test measures backward slip on the ball of the foot with the heel raised and forward heel slip at a 7° angle and boots that pass this additional test can be marked SR.

These tests replace the previous SRA and SRB tests in the 2011 version of the EN 20345 standard. SRA testing was similar to the mandatory test in the current standard and was assessed using soapy water on a ceramic tile. The SRB test used oil (Glycerol) on a steel plate; this test had a very low pass/fail limit and the error in measurement was +/- 50%. The pass value is so low that the probability of a fall in this environment is still high, which is why this test has now been replaced. The SRC marking in the 2011 standard indicated that boots had passed both SRA and SRB tests.

The vulcanised rubber sole on Workmaster™ boots produces very high levels of slip resistance with soapy water on a ceramic tile (the most common use case scenario), and these test results have been confirmed during customer wear tests. Due to the performance characteristics of the sole material, boots with our vulcanised rubber sole also achieve a pass on the new SR (glycerine on a ceramic tile) test and the previous SRB (oil on steel test). Boots with a vulcanised sole that have been assessed to the new standard are marked EN 20345:2022+A1:2024 SR, boots that have not yet been reassessed are marked EN 20345:2011 SRC.

Note: Some manufacturers add rubber to PVC to improve its resistance to fuel & oil, but this is not the same as a vulcanised sole and does not improve slip performance.

Boot Compounds

We have six compound families we use in our Workmaster™ boots that enable us to provide solutions for a wide range of industries and applications:

Hazmax™ Widely used and highly effective chemical protection

Dielectric Protection for high voltage workers

Cryotuff Extremely durable providing protection against oils, common cleaning agents and solvents

Cryolite Lightweight and environmentally friendly with excellent low temperature performance

ISOTEC Heat and flame resistant

Solestar A cost effective PVC based compound for general purpose footwear

HAZMAX™ CHEMICAL PROTECTIVE SAFETY BOOTS

For hazardous or aggressive chemicals our Hazmax™ range of boots offer unrivaled chemical protection. Hazmax™ safety boots are widely used by emergency responders and people working with or transporting aggressive or other hazardous chemicals. Hazmax™ boots and overboots are certified to EN13832-3, the European standard for chemical protective footwear and meet the requirements of NFPA 1991 for chemical vapour protection.

Hazmax™ vs. The Competition: 30 Years of Proven Safety

The Hazmax™ boot has been the industry gold standard for chemical protective footwear for over 30 years, with a continual process of evolution and improvement over this time.

With over 32 hours permeation resistance to numerous strong acids, including 98% Sulphuric Acid, and permeation test data for an extensive range of toxic and aggressive chemicals, Hazmax boots are trusted by industry and the emergency services worldwide.

Recently, several boot manufacturers have decided to enter the chemical safety boot market. So, how does the Hazmax boot compare to a typical competitor?

Protective Footwear Standards

- EN 13832-3:2006

Footwear protecting against chemicals. Requirements for footwear highly resistant to chemicals.

- EN 50321:2018

Live Working - Footwear For Electrical Protection - Insulating Footwear And Overboots. Defines the requirements and testing for PPE footwear used as electrical insulating footwear and overboots used for working live or close to live parts on installations up to 36,000V AC, and DC requirements. This replaces EN 50321:1999.

- ASTM F1117-03 (2013)

Specification for Dielectric Footwear. Covers acceptance testing of dielectric overfoot and overshoe footwear designed to provide additional isolation or insulation of workers if in accidental contact with energized electrical conductors, apparatus, or circuits.

- PPE Regulation (EU) 2016/425 - Personal Protective Equipment

The Regulation defines “essential requirements” which PPE must satisfy at the time of manufacture and before it is placed on the European market: the general requirements applicable to all PPE; the additional requirements specific to certain types of PPE; and also the additional requirements specific to particular risks.

- EN ISO 20347:2012

Specifies basic and additional (optional) requirements for occupational footwear that is not exposed to any mechanical risks (impact or compression) on the toe.

- EN ISO 20345:2011 & EN ISO 20347:2012 Markings:

SB Meets the basic requirements of safety footwear in EN20345:2011

S5 As SB, but with the following additional requirements: Closed seat region, Antistatic properties, Energy absorption of seat region, Resistance to fuel oil, Penetration resistance, Cleated outsole.

HRO Outsole - Resistance to hot contact

SRA Slip resistance on ceramic tile floor with NaLS

SRC Slip resistance on ceraminc file floors with NaLs (SRA) and slip resistance on steel floor with glycerol (SRB)

FO Outsole - Resistance to fuel oil

CI Cold insulation of sole complex

E Energy absorption of seat (heel) region

P Penetration resistance

CR Cut resistance

A Antistatic

I Insulating

How we test our boots

PHYSICAL & MECHANICAL TESTING

We test every element of our boots to ensure their safety, performance and comfort. Some testing is carried out at our factory while some is undertaken for us at specialist accredited testing laboratories. Our factory can conduct, high-voltage testing, deformation testing on toecaps, flex cracking and low temperature flex cracking on boot compounds. Boots are also extensively trialled by users to check for comfort, wear and durability during development.

Chemical Permeation Testing

We thoroughly test our compounds materials for their chemical resistance at an independent UKAS accredited laboratory for chemical permeation testing and for testing the physical properties of materials. We regularly re-test our fabrics and seams to ensure quality.

HIGH VOLTAGE (DIELECTRIC) TESTING

Every pair of Workmaster™ Dielectric boots is electrically tested to EN 50321:2000 prior to dispatch. The test involves filling the boot with water and submerging it in a water bath, an electrode is placed inside the boot, with a second electrode connected to the metal frame of the bath. A test voltage is then applied. Boots are tested at 5kV for leakage current and are then submitted to a withstand test at 10kV for three minutes.

We regularly test samples from production at 20kV (which requires a slightly different setup for the test rig), and customers can specify boots are tested at this higher voltage if required.

INSULATING (DIELECTRIC) FOOTWEAR FOR LIVE WORKING

Insulating boots or overboots are an essential item of personal protective equipment for safeguarding workers against electric shock, ensuring that those working on, or close to, live electrical equipment are adequately protected.

STEP VOLTAGE HAZARDS

Step voltage is the voltage between the feet of a person standing near an energized grounded object during an electrical fault, such as a power line short circuit or even a lightning strike. In this situation electric current flows through the surrounding soil and the resistivity of the soil creates a potential gradient that is at its highest at the fault and decreases as you get further away. If a persons feet are different distances from the fault, the difference in electrical potential (voltage) between them can pose a significant risk, as current can pass through their body from one foot to the other. The primary danger associated with step voltage is the potential for severe electric shock, which can lead to serious injury or even death. Understanding and mitigating the risks of step voltage is crucial for ensuring safety in areas prone to electrical faults, such as pylons, substations and high voltage industrial environments.

Although step voltage passes through a persons legs and groin, avoiding vital organs, when a person is subjected to a high step voltage, their muscles will contract, potentially causing them to fall to the ground. This not only increases the current acting on the body, but also changes the path of the current, potentially causing it to flow across the heart or through the head; this type of electric shock can be fatal.

Sizing

Our boots and overboots are available in a broad range of sizes. Workmaster™ Compact overboots are designed for use over a conventional safety shoe or safety trainer, while the Maxi overboots are designed for use over traditional safety boots.

Workmaster™ boots are generously sized as they are designed to accommodate wearers with thicker socks or a thermal lining. We recommend downloading the A3 Size Guide below to ensure the perfect fit.

Boot Sizing

| UK | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| EU | 35 | 36 | 37 | 39 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 49 | 50 |

| US | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

OVERBoot Sizing

| Medium | Large | Extra-Large | |

| UK | 6 - 8 | 9 - 11 | 12 - 14 |

| EU | 39 - 42 | 43 - 45 | 46 - 49 |

| US | 7 - 9 | 10 - 12 | 13 - 15 |